Solar Inverter Step up Integrated Transformer

FUTURE-SOLUTION

BE PART OF THE GLOBAL SHIFT TOWARDS CLEAN,

SUSTAINABLE ENERGY SOURCES.

01

Introduction

Solar inverter step-up transformer

Amorphous alloy core

- Energy efficiency: No-load loss reduced to 0.15W/kg (measured in a Sineng Electric desert project).

- Structural innovation: Elliptical cross-section design (magnetic circuit shortened by 12%, weight reduced by 8%)

66kV high-voltage direct connection architecture

- Eliminating 35kV medium-voltage switchgear reduces system costs by 22%.

- Epoxy resin vacuum casting (partial discharge <5pC)

Three-proof reinforced design

- Salt spray corrosion: IP65+C5 anti-corrosion, life expectancy 50% longer in dust/salt spray environments

Intelligent thermal integration management

- Dry-type transformer: PTC thermistor + axial flow fan linkage (hot spot temperature rise control <65K)

02

Application Scenario

Scenario-based transformer technology solutions

RENEWABLE ENERGY SOURCES OFFER NUMEROUS ADVANTAGES THAT CONTRIBUTE TO A SUSTAINABLE AND THRIVING FUTURE FOR OUR PLANET HRIVING FUTURE FOR OUR PLANET.

Coastal Mudflat Scene

Core Challenge: 50°C High Temperature + Dust Corrosion

Transformer Solution:

- Amorphous Alloy Core (No-Load Loss 0.28W/kg)

- Stainless Steel Corrugated Fuel Tank (C5M Corrosion Resistance Grade)

- Top Shade and Heat Dissipation Wing Design (Reduces Internal Temperature by 15°C)

High-Altitude Cold Area Scene

Anti-corrosion Technology:

- Fuel tank triple coating: zinc-rich primer + epoxy micaceous iron oxide + polyurethane topcoat

- Casing silicone rubber composite insulation (hydrophobicity Class HC1)

Measured data: Salt spray test for 3000 hours, corrosion rate <0.5μm/year

Desert Power Station Scene

Low-Temperature Compatibility:

Synthetic ester oil (freezing point -45°C, compared to -22°C for standard mineral oil)

Winding inter-turn insulation thickened by 0.5mm (to prevent cold cracking)

Operational Verification: No faults recorded during cold start at -40°C

our product

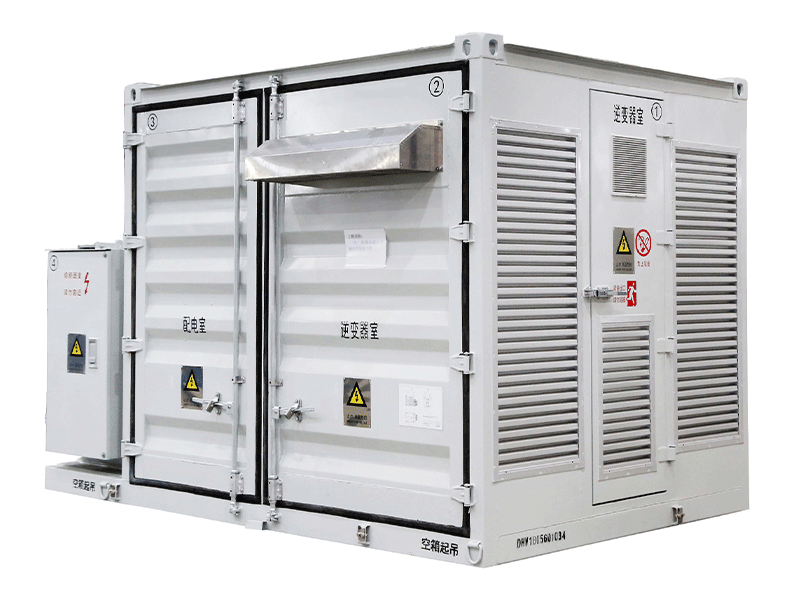

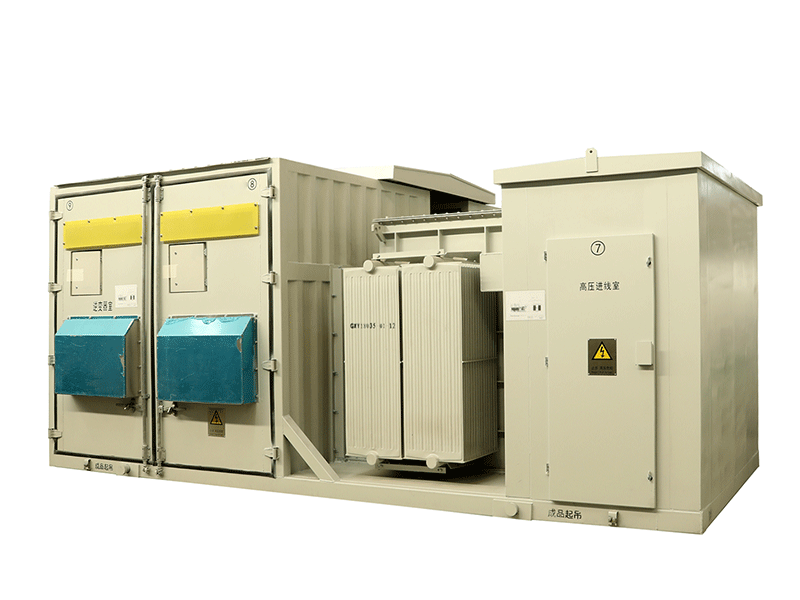

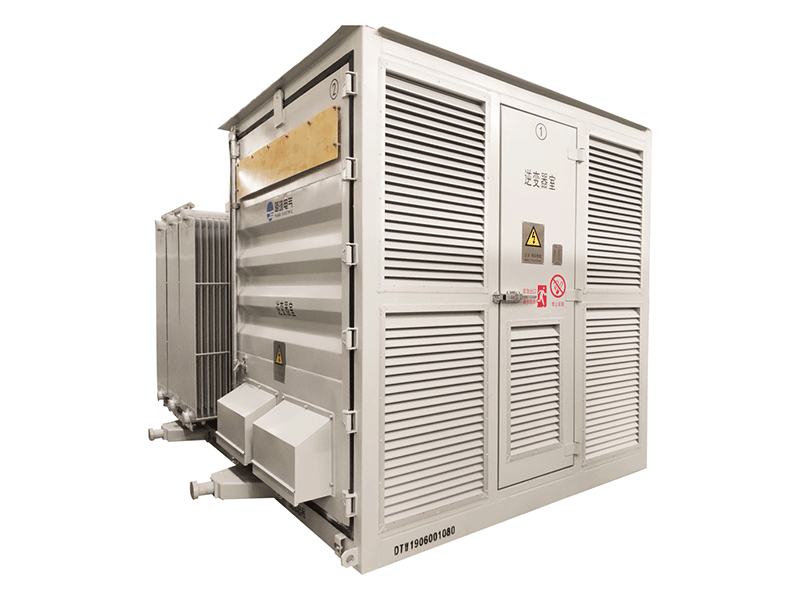

Solar Inverter Integrated Pad-Mounted Transformer

Scope of application: <3.0MW

High-voltage solution: Full Range of Plug-in Fuses

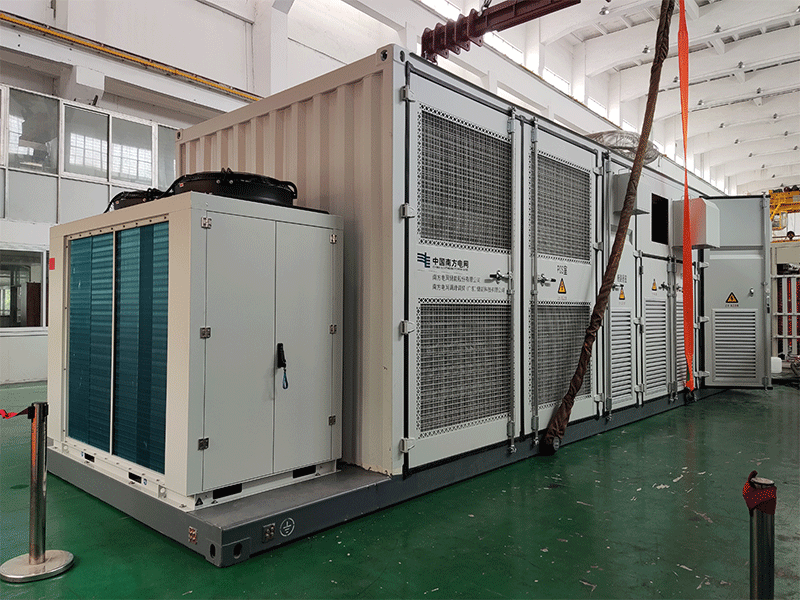

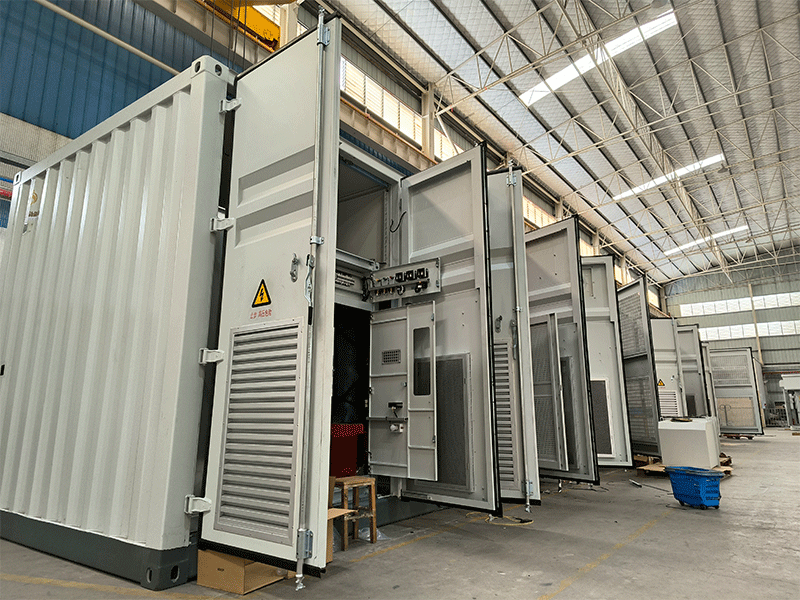

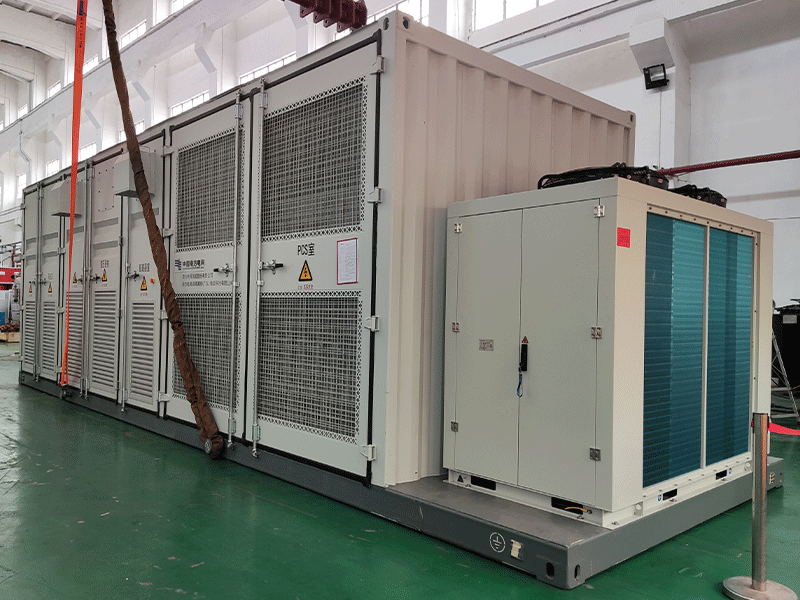

Solar Inverter Step Up Integrated Compact Substation

Scope of application: >3.0MW

High-voltage solution: Vacuum Load Switch + Fuse Combination/Vacuum Circuit Breaker

Solar Energy Storage

GET INVOLVED

Be a Part of the Global Movement

The competition in the photovoltaic inverter market is essentially a competition in transformer technology. Only manufacturers with core competencies in amorphous alloys, 66kV direct connection, and extreme environment protection are worthy of selection.