Smart Factory

Factory Highlights Equipment

Factory equipment

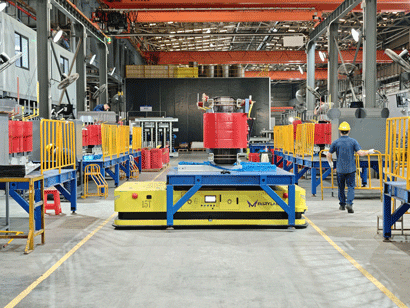

Intelligent warehousing system

Intelligent transport vehicle

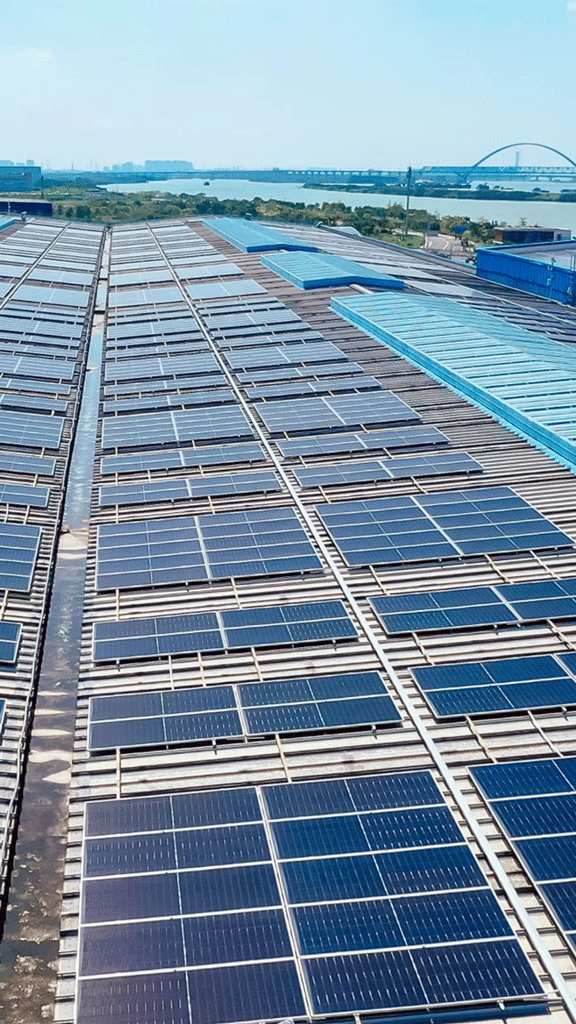

Solar energy storage system

How is a dry-type transformer produced?

Steel cutting

Steel cutting

The use of cold-rolled grain-oriented silicon steel sheets helps reduce hysteresis loss.

core stacking

core stacking

The "stepping lamination" method and 45° fully oblique joint structure are adopted to effectively reduce the loss when the magnetic flux turns in the magnetic circuit and the air gap at the joints.

coiling

coiling

High-voltage coils are usually tightly wound using high-speed winding machines to ensure the concentricity and tightness of the coils.

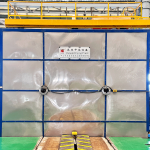

pre-Drying

pre-Drying

Insulating parts such as coils are pre-dried before casting to remove moisture.

Vacuum casting

Vacuum casting

The epoxy resin mixture is poured into the mold containing the coil under vacuum.

Assembling

Assembling

Assemble the insulated coils, cores and other components.

Final Test

Final Test

Tests: Voltage ratio, winding resistance, no-load loss, load loss, power frequency withstand voltage, induced withstand voltage, partial discharge level.

packing

packing

Choose the appropriate packaging material and method based on the size of the transformer and the transportation distance.

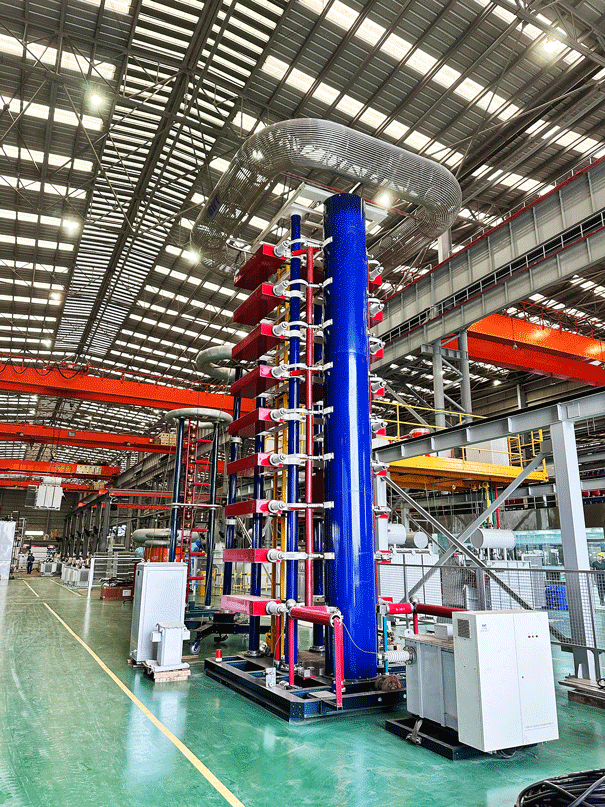

Lightning Shock Test Bench

Quality control verification card are used for the complete manufacturing process thus assuring traceability of all operations.

- Verify the reliability of the insulation design

- Cooperation of inspection and protection measures

- Quality control and type certification

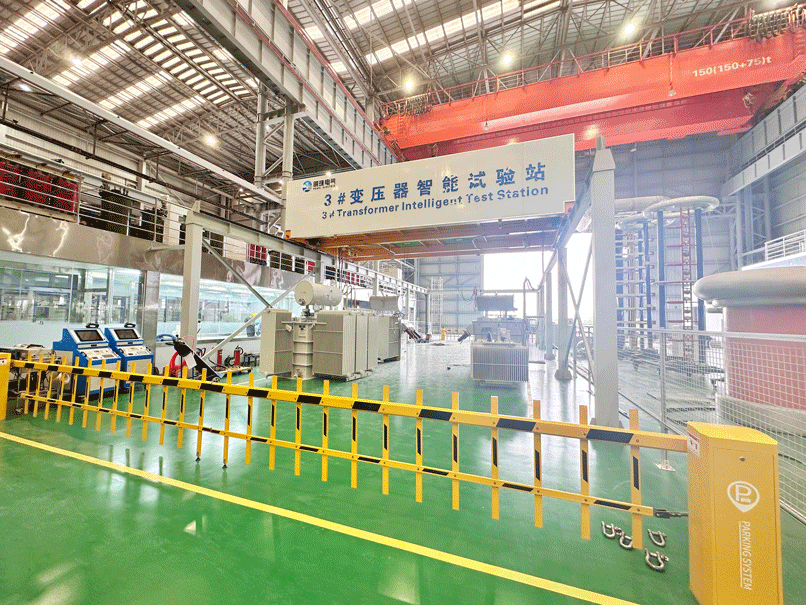

Transformer Intelligent test station

Quality control verification card are used for the complete manufacturing process thus essuring traceability of all operations.

- 100% incoming material control as well as inspections at major supplier's premises

- Extensive quality training for all employees

- Certificate:ISO9001, ISO14001, OHSAS18001

Contact Us

We warmly welcome you to visit our factory, simply communicate with our sales representative beforehand.