future energy: wind power

Take the first step

towards energy independence and a sustainable future!

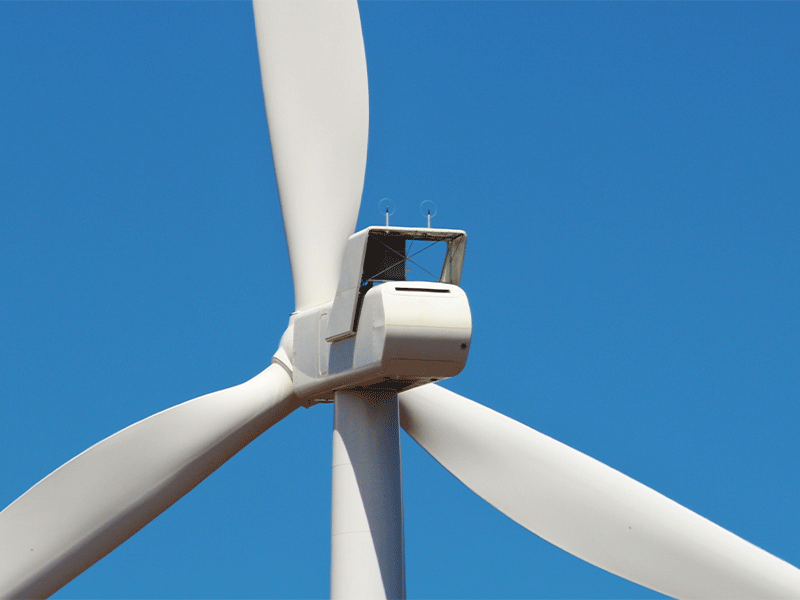

The offshore wind turbine nacelle/tower transformer

operate in one of the harshest environments for power equipment.

They will face the following challenges:

Space/Weight Limitation

Nacelle/tower space is limited, so transformers must be compact and lightweight to avoid excessive load on the structure. Dry-type designs are often used, combining space efficiency with corrosion resistance for offshore conditions.

Salt Spray Corrosion

High salt spray environment will have higher requirements on the anti-corrosion process of transformers and the packaging process of dry-type transformers

High Temperature/Humidity

High temperature and high humidity environment requires dry-type transformers to meet F-class/H-class epoxy casting

Difficult Maintenance

Combined with the SCADA system, early fault warning and status evaluation can be achieved, supporting predictive maintenance and reducing unnecessary offshore operation and maintenance trips.

Q: How Pearl Electric Address These Challenges?

A: The offshore wind turbine nacelle/tower transformer - Cast resin Dry Type Transformer

*We are one of the top five dry-type transformer manufacturers in China

Cast Resin Dry Type Transformer (CRT)

1.The winding is fully encapsulated with epoxy resin to protect it from moisture, dust, corrosion and other environmental factors. (66kV model reaches C5H level anti-corrosion process)

2.Due to its non-hygroscopic, non-flammable and maintenance-free characteristics, it is suitable for high temperature and high humidity areas and space-constrained installation areas.

3.Rated power range: 25 kVA to 12,500 kVA, Insulation class: Class-F (Temperature Rise: 40K, Full-Load Operating Temperature: 70-80℃, Temperature Resistance 155℃-180℃).

4.Combined with the SCADA system, early fault warning and status evaluation can be achieved, supporting predictive maintenance.

5.The convenience of maintenance was fully taken into consideration during the design phase of the transformer, and it can be easily disassembled into a whole piece for entry and exit through the cabin cover.

6.Air Forced + Water cooling internal circulation, high heat dissipation efficiency.

The "Triple-High" Evolution

As offshore wind embraces:

- High-voltage

- High-capacity

- High-reliability

Voltage Leap

66kV becomes standard; 110kV enables deep-water economics

Smart O&M

Digital twins + predictive maintenance

Green Shift

Epoxy resin cast transformer is environmentally friendly and flame retardant

Selection Guide: Key Specs & Certifications

Performance Metrics

- Voltage: 35kV (phasing out) → 66kV (mainstream) → 110kV (future)

- Capacity: ≥105% turbine rating (e.g., 17MVA for 16MW turbine)

- Losses: <0.8W/kg no-load loss, <1.2% load loss (EU Tier 3)

Mandatory Certifications

- EU: CE + EN 60076 + DNV-GL (floating)

- North America: UL/CUL + IEEE C57.18

- Asia/Mideast: ESMA (UAE), SNI (Indonesia), CQC (China)

Get in touch with us, switch to clean energy right now!

Discover the benefits of sustainable energy for your home or business.